StarLifter

The C-141, Lockheed's High Speed Flying Truck

by Harold H. Martin

The Most Forgiving Airplane

A VETERAN test pilot like Leo Sullivan does not look upon the first flight of a new airplane as a particularly hazardous experience. When he taxis out to the head of the runway, runs his check list with his copilot, and shoves the throttles forward to start the takeoff roll, he feels a sense of exhilaration, a tingle of high excitement. But he has no fear of the airplane, no apprehension.

"By the time you've come this far," he says, "the airplane is no stranger to you. You've been living with it a year, two years, maybe more. As soon as your company enters a competition to build a new plane, the test pilots begin to follow the project, looking over the shoulder of the preliminary design engineers. Your main interest, of course, is in the flight deck, the place you are going to work. But every detail of how that plane is designed and how it will be put together is of concern to you. You follow the systems designers until you know the hydraulics, the electronics, the flight controls, the gear-up, gear-down machinery, until they are as familiar to you as the back of your own hand. You study the wind tunnel tests, and all the static tests. If you see anything being designed into the airplane that makes you pucker up a little, you make your comments then and there, so all they have to tear up is a piece of drawing paper.

"Then you watch everything being put together. So, when that airplane finally rolls out into the sunshine, you know it as a friend. In the case of the 141, we had been watching it take shape for two years. When we first flew the C-5, we had been following it, on the drawing boards and down the assembly line., for three and a half years. This gives you confidence. You know the engines aren't going to quit on you. You know the wings aren't going to fall off when you lift off the ground. You are confident the landing gear is not going to buckle under you when you land."

No plane just rolls out of the hangar and takes off on its first flight, of course. The care with which Sullivan and his pilots watch the design and manufacturing process seems almost casual compared to the concentrated scrutiny they give the aircraft during the weeks when it is being readied for its maiden flight. They sit in the plane for hours, running up the engines, turning the switches off and on, pushing the buttons, making the dials and gauges light up, operating the flight controls.

"What you try to do is get a sense of the characteristics of this plane," says Sullivan, "a sense of its dynamics, its normal noise level, normal vibrations, the feel of the life that comes into it when the engines are running and all its generators are turning out the juice, and it is ready to roll. No test pilot can live out his life in this business without a lot of luck-but much of this so-called luck is just intuition, a sixth sense that tells you, 'Oh-oh! Better take a look around. Something doesn't sound quite right, or feel quite the way it should.1 There's a faint aroma of trouble in the air.

"You start the taxi runs off slowly, just driving the plane around, turning it right and left. If no bugs develop, you then build on up to just under takeoff speed, to get the feel of the flight controls as best you can before you start to fly. On the big ships the elevators and the ailerons and the rudder all operate on hydraulic power. The pilot does not actually feel the control systems responding, the pressure of the air on the control surfaces, as he does when he is flying a light plane. He feels an artificial resistance, fed back to his hands, and to his feet on the rudder pedals, through a system of springs, set at a certain tension. It's like driving a car with automatic steering."

In the high-speed taxi runs the thrust reversers and the brakes are tested, and the device that dampens the nosewheel shimmy is checked out. Then more and more elevator is cranked in, at higher and higher speeds, until a light on the controls panel comes on that means that the nosewheel is off the ground and the plane is trying to fly.

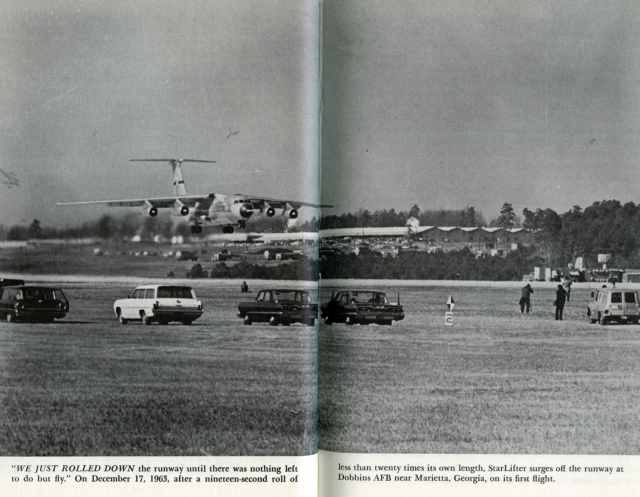

Finally, says Sullivan, there comes a day when your own built-in instrumentation tells you there's no sense in fooling around any longer. Nothing is leaking. Everything sounds good, and looks good. You feel good about it, and there's that big blue sky up there. So you turn her nose to the east to get the advantage of that eighty-foot downhill roll at Dobbins, and you pour on the coal and you get your "Eeper" up-your engine-pressure ratio-and she starts rolling, and when you hit your go or no-go speed, you keep rolling till you reach your takeoff speed for that weight and configuration. Then the copilot yells "Rotate," and you haul back on the yoke, and up she goes. You are in a flying machine.

"And if you don't think those slide-rule guys are smart, let me tell you something. When we flew the C-141 for the first time, it lifted off the ground within one knot of where a guy named Frank Wilson, over in preliminary design, told me it would six months before."

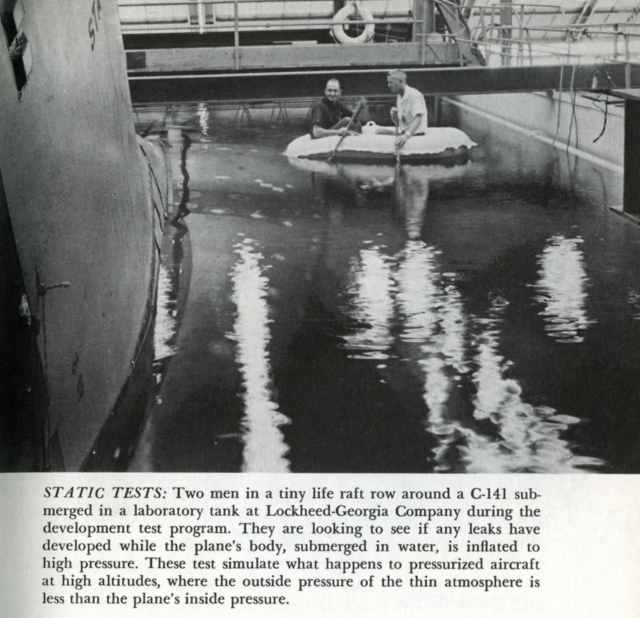

The first flight, of course, is always a short hop, cautiously carried out within sight of the field with the gear down and the plane empty of cargo and unpressurized. It seeks to prove little more than what everybody knows already-that the plane will fly and is controllable in the air. The tough testing is still to come-the slow progression, step by step, from one threshold of performance to another-the flutter tests and the stall tests, the high-speed dives that put great strain upon the airframe-and sometimes upon the nerves of the test pilot. Compared to these maneuvers the straight and level first flight is an aerial joy ride. There are limits, of course, beyond which testing cannot be carried on in the manned aircraft. What a new plane ultimately can endure is discovered only in static testing on the ground in which each separate component is put under greater and greater strain until it breaks or fails to function-or, as often happens, so far exceeds its design specifications that there is no need for further testing.

First flights show what the engineers have done right. The tests that follow, in the air and on the ground, uncover their mistakes. When a manufacturer designs a new plane, whether it be an airliner to carry people or an airlifter to haul freight, his first consideration is safety. The one thing in the world he does not want is a plane with his name on it to break up in a Midwestern thunderstorm and scatter its crew and cargo over half of Iowa.

So each designer of each component part-landing gear, nose section, fuselage, wing, and tail assembly-feels a strong compulsion to design the strongest and safest structure he can put together. The result, when all these parts are mated, is a fat airplane, for strength means weight. The airplane manufacturer fights an unending battle against unnecessary weight, for he knows that each pound that goes into the airframe means one less pound of payload the plane can carry. Seemingly inconsequential little things, such as putting on the paint one-thousandth of an inch too thick, can add 200 pounds to the empty weight. It is not surprising, therefore, that in a huge assembly hangar where planes are being put together you will see signs bearing the seemingly childish admonition:

HATE WEIGHT ..... LOVE LIFT!

and that rewards such as cigarette lighters and tieclasps bearing the British pound symbol are given plane assemblers who can show the designers ways to eliminate even a few ounces here and there.

Once weight is designed into the plane, getting it out is as difficult as trimming the lard off a fat man's waistline. The easier way is to eliminate it in the original design, and then to add it, if needed, if more strength is required.

Gordon Forbes, who is now Lockheed's chief experimental and avionics engineer, describes the unending search for the happy compromise, the ideal ratio of strength to safety, weight to lift: "Safety is number one, of course. It takes precedence over every other requirement. But we try to be awfully sure we are attaining strength, and safety, as cheaply as possible in terms of weight. This may be accomplished in several ways. By going to such metals as titanium and beryllium, which are strong enough, but lighter than aluminum or steel and, of course,441 STARLIFTER

fantastically more expensive. By the use of laminated honeycomb plastic bonded to metal surfaces. Or by using just a shade less metal, in the weight and stress members, than the tables would call for. You try to keep just a wee bit under, never over, the machine's strength. The stress engineer, for example, looks at the skin of an airplane, and he figures that sheet metal twenty-six thousandths of an inch thick just might carry the load as well as metal that was thirty thousandths thick. If so, it means a saving in a big airplane of several thousand pounds in weight. So he tries the thinner metal, and he puts it through all sorts of static tests, putting greater and greater loads upon it, until he finally finds the point at which it breaks. If this is somewhere very close to a hundred and fifty percent of the design load, well and good. A member that will support fifty percent more than the heaviest load that will probably ever be placed upon it is safe enough. If it goes beyond that, it is too heavy. Its strength can be trimmed down. If, on the other hand, it fails at around a hundred and thirty percent of design load, strength must be added to bring it up to a hundred and fifty percent. If it fails at a hundred percent or less, you have to scrap the whole design and start over."

In this kind of testing, failures are expected, for it is the purpose of static testing to discover points of weakness on the ground, under controlled conditions, where no lives are at stake. The StarLifter, in the course of its development testing, had its share of failures, comparable to those that afflicted its stable-mate, the C-5, later on. They attracted no public attention at the time, however, for the mood of the nation in 1963 was not one of rancor toward the military as it was in 1969. There was little public outcry, for example, and no Congressional investigation when a StarLifter wing strut broke too soon in static tests, and ramp and cargo doors blew open under pressure testing. A petal door, one of the outer clamshell doors that give the plane its smooth configuration aft, fell off over Rome, Georgia, during yaw tests, and the flaps, when deflected, caused fierce buffeting. The steering column, which worked fine, had to be redesigned because it was too complicated to manufacture. Similar bugs crop up in every new aircraft, and Chuck Wagner and Max

Hammond took them in stride. Once they knew the problem, their stress and dynamics people had no trouble figuring out the proper fix. The weak strut was beefed up, the flap problem was solved by the use of fences and fillets, slots and varies, that reduced buffeting to a minimum, and the locks and latches that sealed shut the ramp and cargo doors were redesigned. Not all first fixes work, of course. Months after the change in the locks and latches, a pressure door blew open in the sky over Wake Island, dropping the baggage of a planeload of troops into the Pacific.

Neither can all the weaknesses in an aircraft's structure, or flaws in its design, be discovered in static tests alone, or even in flight tests, for both of these apply maximum loads to the airplane over brief periods of time. Fatigue testing, on the other hand, puts a different type of strain on the plane. In fatigue tests the plane's components are cycled through the stresses and strains of normal operation in an accelerated program that crams two lifetimes of service into three years or less of simulated flight. The StarLifter was designed for a lifetime of 30,000 hours in the air. In this period it was assumed that the plane would take off, climb, cruise, descend, and land some 12,000 times. Compatible sections of the plane were clamped into test jigs, iron monsters which, in the words of Gordon Forbes, "put them through recurring cycles of the shake, rattle, rock and roll they would endure in two lifetimes-or sixty thousand hours-of simulated flight." Day after day, week after week, month after month, the landing gear was raised and lowered, the wings flexed under the strains imposed in climb and level flight. The flight controls, such as ailerons and rudders, were cycled as many as five million times as the fatigue test people sought to discover where weaknesses might show up ten years in the future.

No tests yet devised, of course, can take the place of actual flight under normal operating conditions in spotlighting hidden flaws. The StarLifter's nosewheel, for example, had a tendency to shimmy when the plane was rolling fast in taxi tests, but a damper was devised which seemed to work perfectly when tested. Curiously, as soon as the StarLifter went into service with the line squadrons, the nose started shimmying again. Pilots putting down at Guam after a flight from Hickam and at Elmendorf after a flight from Charleston reported the problem. Whenever a plane landed after a long flight at high altitudes, the wobble appeared. After short flights, the damper was damping as it should. This proved to be a clue. The damper had been tested back in Georgia after brief test flights at low altitudes where air temperatures were moderate. Engineering detective work found the trouble. The damper was failing because the hydraulic fluid that actuated it shrank in volume after long exposure to the bitter cold at high altitudes. The cure was simple-pump in morejS/STARLIFTER

fluid from the main hydraulic reservoir when the plane came in to land. Some problems just came and went. There was a mysterious "shibble," a combination shake and nibble, that could be felt in the pilot's yoke in the early StarLifter. It disappeared; no one knows why.

The StarLifter structures that served their time in the static and fatigue tests have long since gone to the Pea Patch, a field at Lockheed-Georgia where the weary bones of test-racked planes find rest. Whenever the strain gauges revealed a point of weakness, fixes were made and structures incorporating these changes were clamped into the test jigs, for each change in design or material used must undergo its own double lifetime of tests.

The exciting tests, obviously, take place in the air. No manned plane is ever subjected to stresses as great as those its components have already survived in static testing on the ground. But planes in the air do not always behave as the wind-tunnel and the static tests predict, and there is always the possibility that something can go tragically wrong. For this reason flight testing proceeds slowly and cautiously, moving upward knot by knot, pound by pound, until the plane's limits are reached. To carry out these carefully planned but still potentially hazardous procedures, the aircraft manufacturers look for certain qualities in the men they hire as test pilots. Neither the thrillseeker nor the overbold need apply.

"Basically what you are looking for," says Forbes, "is a man with a family of whom he is very fond, and to whom he is eager to return at the end of each working day. A man not too young, not too old. A consummate pilot, of course, but a man who also has a good sound basic background in engineering. We are not looking for the wild-blue-yonder type of test pilot. He may thrill the watchers of the late, late show, but he is not the man we want to fly our machine. There's too much at stake, both in money and reputation, to risk either at the hands of some aerial hot rodder. The good test pilot must have a good seat-of-the-pants feel of the airplane, but he must be able to read the instruments and interpret them properly so as to analyze, or help the people on the ground to analyze, just what it is the seat of his pants is telling him."

By these criteria, Walt Hensleigh, who became Lockheed-Georgia's chief engineering test pilot when Leo Sullivan moved up to assistant development engineer, seems to have all the credentials. A calm, soft-spoken man who wears glasses to read, though not to fly, he smokes a corncob pipe and looks more like a professor of math than a test pilot. Hensleigh was born in Seattle, raised in southern Mississippi, and educated at Mississippi State, where he graduated with a B.S. in Aeronautical Engineering and the rank of second lieutenant in the Army Reserve. When World War II came along, he was assigned, curiously, to the Coast Guard, where he spent ten restless months until he got a transfer to the Air Force, where he immediately signed up for pilot training. A clear-thinking man with a gift for making complex things seem simple, Hensleigh's professorial qualities were recognized early, and on graduating from flight training he was assigned as an instructor on B-24's. Tiring of the teaching assignment, he went back to school himself, taking aircraft engineering at Wright Patterson Air Force Base. From there he went into flight testing, which has been his job ever since. He came to Lockheed as a test pilot in 1955, after eight years as a test pilot with Fair-child Aviation Company, and a short hitch with North American as a guidance engineer in its missile program. "My little B.S. didn't count for much," he says, "with all those PHD's. On top of that, it wasn't a flying job."

Hensleigh's main concern is now with the C-5, but he still remembers, in pleased amazement, the fantastic success of the C-141 test program. No other plane in history, he thinks, ever got into line service so quickly and did its job with fewer stand-downs for repairs.

He was not on the first flight with Sullivan and Hank Dees, but he played a big part in the tests thereafter. In a test program, the first five planes off the line are usually assigned by the manufacturer to separate test roles. No. 1 is used for checking flight characteristics, stability, and control. A feature of this program is the flutter tests, a sometimes unnerving procedure in which artificial shakers are attached to wings and tail surfaces to set up vibrations of varying frequency. This simulates the flutter that sets up when a plane flies through turbulent air at high speeds, and unless the plane is so designed that it will dampen these vibrations, the control surfaces, the wing, or the tail may be torn away. Strain gauges, which are thin wires attached to the plane through which electricity is passed, transmit to the cockpit and to computers on the ground the amount of stress the test panels are undergoing. Buffeting and the feel of the controls tell the pilot when the load is becoming critical, and some ground monitors with the experience of Tom Haley can tell when trouble is coming even before the pilot is aware of it. In the test plane the shakers can be shut off instantly, and the plane, if it is properly designed, immediately dampens out the vibration. In actual flight through stormy weather, or at high speeds at certain altitudes, flutter may occur spontaneously. The only cure in this situation is to slow down. The purpose of the tests, of course, is to determine the plane's capacity to dampen vibrations, and to know at what speeds it may be safely flown without setting up a dangerous flutter.

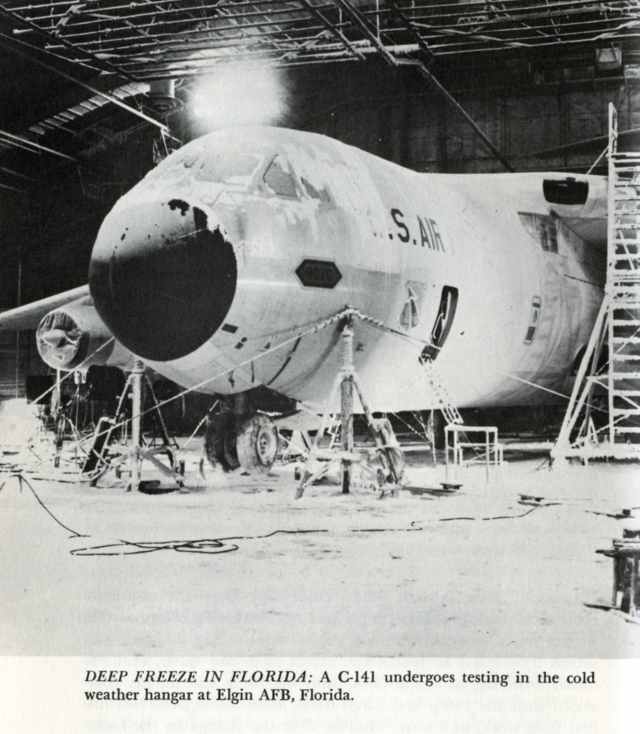

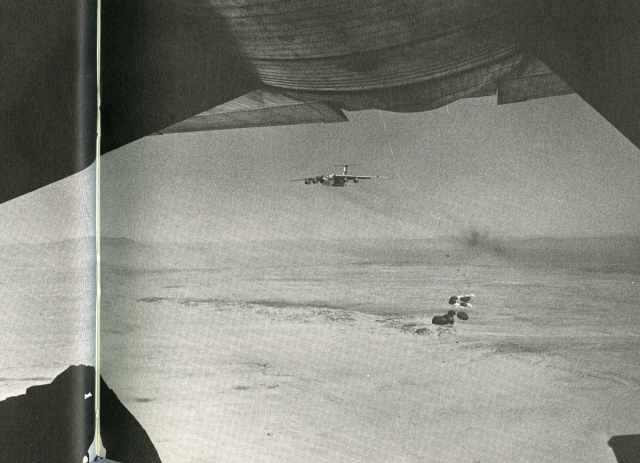

Once this speed envelope is determined, the second plane off the line can go into its performance tests and the third can be put through the final wringing out, which is a torturing series of maneuvers to test the plane's structural integrity. The fourth plane is used to test the plane's auxiliary systems, including its capacity to function under either polar or tropical conditions, and the fifth is used to demonstrate to the Air Force and the Army that the plane can carry out the military mission of airdropping paratroops, vehicles, and cargo.

Walt Hensleigh flew the 141 in all these tests at one time or another, but his particular responsibility was the No. 2, the performance test plane. In a program which he describes as being "mainly a lot of tedious precision flying and record keeping," but which sounds hairy enough to a layman, he put the No. 2 StarLifter through its three-engine takeoff tests. In this procedure the pilot starts a normal takeoff roll, cuts one engine, and measures the distance it takes him to get the plane off the ground, the time it takes to climb to cruising altitude, and its feel and performance at cruise.

"It's not particularly hazardous," says Hensleigh, "but it's something you kind of lead into, step by step. You start off light, at a weight you know the three engines can lift, and then you start building up the gross weight little by little until at last you are just barely flying. Or maybe you aren't really flying at all, even though you are airborne. The ground effect, which is the extra lift a plane gets when the air is squeezed between the ground and the wing, is holding you up, but when you get up a few feet higher and lose the ground effect, the plane settles back. By this means you determine the maximum weight the plane can carry on three engines working at full thrust."

Multiengine airplanes can't be flown straight below certain speeds, and it is necessary to determine what that speed level is. So Hensleigh, during performance tests, not only added weight until he reached the maximum the plane could carry; he eased back on the throttle by slow degrees until he found the maximum gross weight and the minimum thrust at which he could control the airplane.

For the three-engine takeoff tests the aircraft was flown to Edwards Air Force Base, California. There the paved runway is three miles long, with seven miles more of smooth dry lake bed beyond that on which to put down in case of emergency.

The StarLifter passed its performance test with ease. "That's the beauty of this plane," Walt Hensleigh says. "It's got what every pilot wants, power to spare. You can put on a full load- seventy thousand pounds-and take off on three engines at a gross weight of three hundred and nineteen thousand pounds, and you can still climb high enough to make a go-around and come back in to land. It is not, of course, a speedy piece of equipment. There are people up there at thirty-five or forty thousand feet who are passing us all the time. But when it comes to takeoff performance, and the ability to climb, and safety with one engine out, those boys in the fast planes can't touch us."

FLIGHT TESTS: Water sprays back (above) from a KC-135 jet tanker onto the nose of a C-141 to produce actual icing conditions in flight. In a performance test(below) a StarLifter sets an unofficial world record by dropping more than 70,000 pounds of simulated cargo in one flight. Its teammate, the C-5, later broke this record by releasing 100,000 pounds on one flight.

The StarLifter's ability to climb like a raped ape, as the airmen describe its upward zoom, gives it another advantage over planes that lack this capability. In a matter of minutes the Star-Lifter can be up and over the weather at its cruising altitude of 35,000 feet while others are still trudging upward through the thunderstorms-the pilots call them thunder bumpers-which are at their most violent from 10,000 to 20,000 feet. With the prodigious lift of its 25-degree sweptback wings, and the 84,000-pound thrust of its four Pratt &: Whitney engines, the StarLifter can also be up and flying after a 4000-foot takeoff roll. The dart-like jets with their sharper 35-degree sweepback may need twice that when loaded.

Fighter jockeys are inclined to look upon the pilots of airlift planes as elderly gentlemen of sedentary habits whose life as aerial truckdrivers involves little excitement and a minimum of risk. This may be true when the cargo planes are in normal operation, but in the testing period, it is the big-ship pilot who is taking the greater risk.

"If a fighter pilot gets in trouble, all he's got to do is reach down between his legs and yank a lever and the ejection seat will blast him out of there," Hensleigh says. "Every time we climb the stairs to the cockpit of a test plane, carrying our parachute and hard hat, we know that it's highly likely that, if we take off in that plane, we'll come back to the ground in it, whether we are flying it or not. There are no ejection seats in a cargo plane to lift you out of there like the hand of God. If you are running a test up there and get in trouble and lose control of the plane, you've got to fight it until at least three other guys walk or climb or crawl or slide for about fifteen or twenty feet- depending on what attitude the plane is in-and climb down a ladder and jump out a door. Then you have to try to make it, with nobody at the controls. If you are above fourteen thousand feet when you jump, your parachute waits until you reach that altitude before opening, so you can breathe in case you forgot your oxygen bottle. And if you are below fourteen thousand, the chute waits three seconds before it opens, so you will be clear of the slip stream. There's no sweat once you get out. The problem is getting downstairs. They've tried to make it as easy as possible. On the C-5, for example, you pull a lever and the high stairway becomes a chute the crew slides down."

No parachutes are provided for either passengers or crew when the StarLifters are in normal operations. During tests, the planes themselves carry parachutes in their tails, particularly for the stall tests. In these maneuvers it is possible that the aircraft, if put inadvertently into too deep a stall, might fall off into an uncontrollable spin. If this happens, the pilot pops the stabilizing chute and the chute lifts the tail up, thus causing the plane to nose down into a dive from which the pilot can easily recover.

Both the C-141 and the C-5 Galaxy carry stabilizing chutes during their more hazardous tests but neither plane has had to use them.

"In the 141," says Hensleigh, "and in the C-5 as well, I was mainly concerned about what would happen in the stall tests. There had been a lot of talk about the T-tail design being particularly susceptible to stalls, and for a while, in the early days of the jet, the commercial planes did have a lot of trouble whenever they ran into weather. But these were planes with their engines aft, which put a lot of weight back toward the tail, and they were also planes that were aerodynamically controlled. The pilot deflected a little tab on the control surface, and the pressure of the air on the tab moved the main control surface up or down. If, in a stall, these little tabs got blanketed, or were in a turbulent flow, you were in trouble. You had no way to recover from the stall."

The StarLifter and the Galaxy are both T-tails, of course, but with their engines forward and with hydraulic actuators serving their controls, they have had no trouble. In the test programs, they pulled out of stalls beautifully. Actually, neither should ever get into a stall. Each plane has a stick-shaker, a warning device that tells the pilot that he is getting close to a stalling attitude by making the stick wobble in his hand. And if he ignores this warning, a stick-pusher then takes over and pushes the nose of the plane down.

The stick-pusher was put on the StarLifter to satisfy FAA requirements, the FAA insisting that any plane it certifies be equipped with everything the "average pilot" might need to ensure the safety of his passengers. Air Force pilots need the stick-shaker warning, but they do not actuate the stick-pusher on the StarLifters that fly the line. Their view is that any pilot careless enough to accidentally stall a StarLifter ought to be in some other business in the first place. Lockheed test pilot Vern Peterson would agree. Peterson, a big, dark, slow moving man, put the No. 3 StarLifter through its structural integrity tests, a program that required him not only to stall the airplane but to put it into steep, high-speed dives, hard turns, and rolling pull-ups, and to cause it to yaw, pitch, and do everything except flip over and fly on its back. Since planes respond differently at different speeds and altitudes, these violent contortions were carried out at high and low speeds and at thirty-five thousand, twenty-two thousand, and ten thousand feet. There were some hairy moments. When a plane in a high-speed dive goes through ten thousand feet at a speed of nine thousand feet a minute, that does not leave too much maneuvering room between it and the ground.

The purpose of these various exercises was to put aerodynamic load, or stress, on the plane's structural members, and to send back these data by means of telemetry to computers on the ground. The tests start at 80 percent of design load and move up gradually to 100 percent, and to make the tests valid each has to be carried out at a certain gross weight, and a prescribed speed and altitude. It requires precision flying by highly skilled pilots, but Vern Peterson makes it sound fairly easy.

"Some of the high-speed tests just can't be done in level flight. You have to stick the plane over in a dive until you get it coming down out of the sky at six or seven thousand feet a minute and then you apply the loads. If it's a positive G-load, I roll it into a two-G turn to the left, holding my speed long enough for the telemetry to measure the load. If I want to pull a negative load, I have to do a roller-coaster maneuver. Say I was in the mid-altitude structural program and wanted to hit a certain speed at twenty-two thousand feet. I'd climb up to around thirty-two thousand and nose over and open the engines wide open and dive down through twenty-two thousand and then pull back on the stick e-a-s-y, like handling a little baby, and come back up, slanting into the speed I want, and hopefully I'd hit it right at twenty-two thousand feet, give or take a couple of thousand under or over. Then I push the nose over into a negative G-load and everything in the airplane that isn't tied down gets up and floats around, weightless."

Things can get fairly wild. Once, in a high-speed diving turn

and rolling pull-out that put a lot of twist on the wing, the plane didn't have quite enough aileron to roll it out, and Peterson sweated heavily before he pulled it up. That had to be fixed. Also, in diving to get up to a speed of Mach .875, the plane got into unusually heavy buffeting. This caused worry until it was discovered that the plane was actually going faster than the instruments showed. The air speed indicator was lagging back at Mach .84 but the ship was reaching speeds of Mach .899 before the pull-out.

"I'd say," said Peterson, dryly, "that the plane proved it had a lot of structural integrity, all right."

Minor surprises kept life from getting dull for the test crew. A thrust reverser blew open in a high-speed dive, which caused the plane to yaw savagely. Peterson immediately slowed down and straightened out, but he still couldn't get the door closed, so he had to kill the engine and land on three engines with the reverser still open. "No sweat," he said. An elevator developed a high frequency flutter at certain speeds that made it feel as if the tail was going to tear off, but Leon Tolve, Lockheed's aerodynamics expert, soon corrected it by beefing up the elevator.

Peterson's structural tests confirmed what Leo Sullivan and Walt Hensleigh had proved in their handling and performance tests. The C-141 had its bugs. But it was a fine, strong airplane, easy to fly and a great performer even with an engine out. "The most forgiving airplane I ever flew," an Air Force pilot said.